GRINS business model focuses on the solution of comprehensive tasks aimed at increasing the production efficiency and creating modern operational areas and rolling sections production complexes.

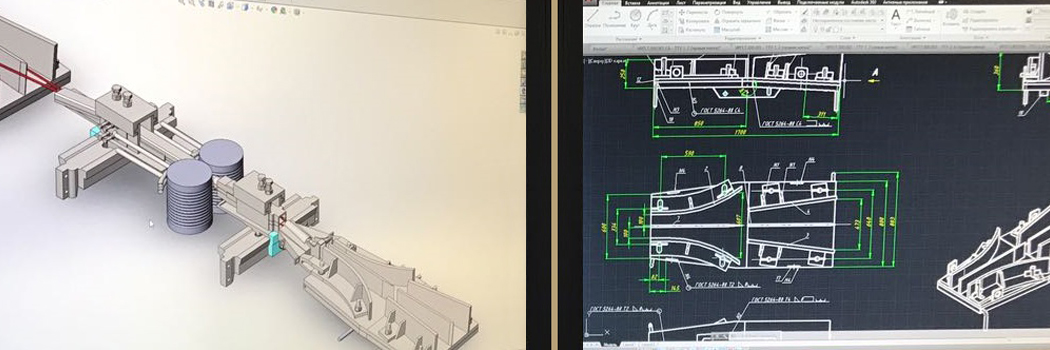

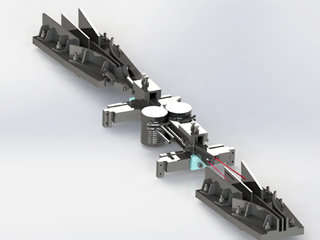

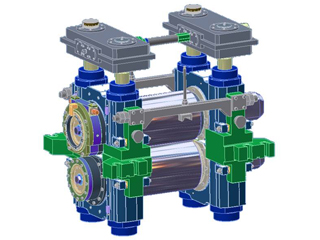

GRINS Company offers comprehensive solutions for creation and reconstruction of rolling sections production process and operational areas. The company undertakes design and survey, establishment of engineering specifications, integration of technological solutions in the production process, supply and commissioning of the equipment, procurement, project management, training.

GRINS business model focuses on the solution of comprehensive tasks aimed at increasing the production efficiency and creating modern operational areas and rolling sections production complexes.

The major advantages of engaging our team to implement a complete-cycle project are as follows: