Use of banded mill rollers in finishing stands of rolling mills allows to:

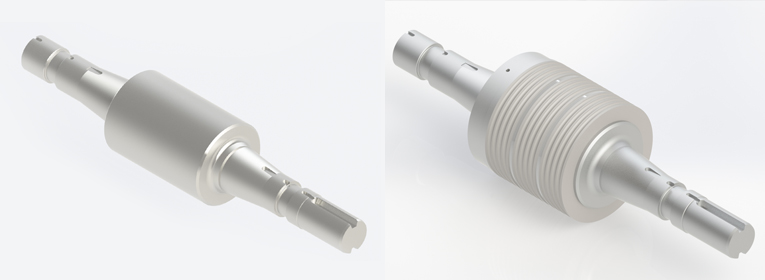

GRINS designs and manufacture composite mill rollers in accordance with the requirements of the customer. GRINS provides a full cycle of design and production of rollers: from design of the process concept to production of equipment and serial production. During the production of rolling rolls, all stages of process development, sample testing, quality control and strength analysis of the finished product are observed.

Banded (composite) rollers allows using the properties of hard-alloy rings and ensure high performance of the mill at optimal prime cost of the tool.

Banded (composite) rolls significantly decrease the time to adjust calibre parameters, reduce labour costs, increase productivity and improve surface quality.

For hot-rolled reinforcing bars and plain bars, special YGR60 hard alloy Is used.

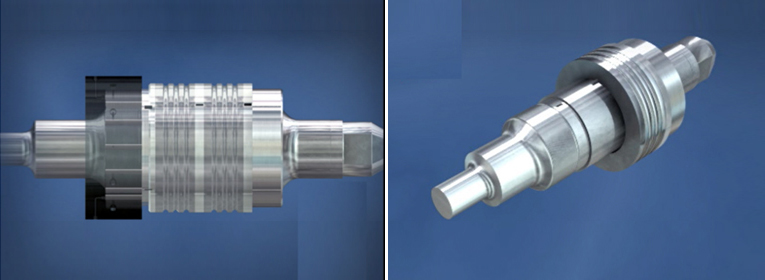

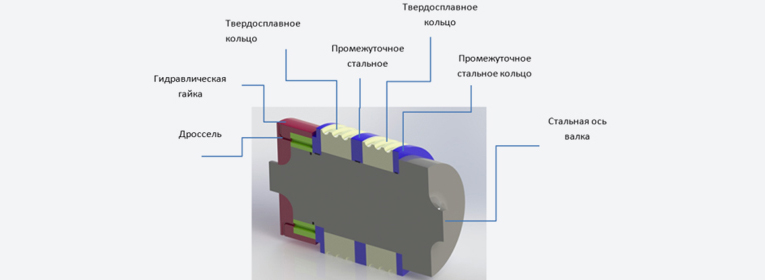

Hard-alloy rings of banded rollers are attached to their axes with locking devices and hydraulic nuts. The oil-fed locking device provides pressure of 100 to 200 MPa, and the hydraulic nut provides the axial force of 500 to 1500 kN; because of this, the hard-ally ring is fixed on the rods. The reliable locking device provides high performance of the composite rings.

GRINS ENGINEERING offers package solutions for design, development and reconstruction of mill rollers, and provides the following services:

Designing and modelling are performed with professional software.

Using its experience in rolling industry, GRINS ENGINEERING has developed a system of comprehensive quality control of production process and finished goods. The system includes control and sampling of material, models and prototypes, operational control of production process and final testing of finished products. Also, the system includes control of the geometric dimensions of the finished mill roller.

High-tech equipment for controlling the quality of materials and finished products, as well as strict adherence to test modes at all stages of production, guarantees high quality of all supplied products.

Mill rollers are manufactured using high-tech equipment by the world's leading manufacturers. Production lines and products are certified under the ISO9001 International Standard.