GRINS offers a wide standard range of metallurgical blades and designs tools according to the customer's technical requirements. GRINS ENGINEERING production features are:

Because of modern high-strength steel, metallurgical plants need cutting tools of high quality. GRINS ENGINEERING produces blades for hot-rolled and cold-rolled products in accordance with today's increased requirements for the level of hardness, strength and wear resistance of the tool.

Metallurgical blades are available in an optimal design for different applications, including:

The distinctive feature of the blades is high hardness and well-trimmed edges without defects. Increased durability and wear resistance of the blades provides an extended service life of the tool. IHigh-strength alloys NMB and NMK are used.

Blades for rolled products of large and medium sectios are made of W6Mo5Cr4V2, 3Cr2W8V, H12, SLD, 5CrW2Si, 6CrW2Si and H13 steel. Use of blades is effective both for large cross-section cutting and for press shear for scrap.

Blades for cutting after continuous caster show enhanced cutting efficiency and durability. The material used for these blades is 6xB2, C or H12 steel. Metallurgical blades are manufactured under GB/1821.1 and GB/1828.2 standards.

To produce the tool, high-alloy, high-strength steel is used.

Disc trimming blades are made of 5CrW2si, 6CrW2Si or H13 steel; blades of larger diameter are made of NMV alloy. When using GE1 or GE2 materials, it is possible to increase tool life up to 2 times.

Blades are characterized by high accuracy and excellent cutting performance and show well-trimmed edges without defects.

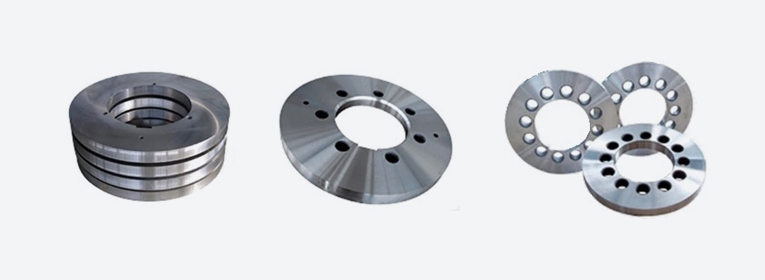

Spacers are used for pipe and tape production. Blades are made of B6M5X4Ф2, 3Х2В8Ф, 3Х2Ф8В, SLD, 5ХВ2С, 6ХВ2С, Н12 and Н13 steel.

Blades are effective for cutting hot-rolled and cold-rolled steel, as well as other metals and alloys.

Metal spacers are characterized by high accuracy of manufacturing and increased durability. They provide precise cutting width and ease of use.

0.4 to 350 mm spacers are made of 12Kh2N4A, 40x, 40hm, 65m and 9HS metal and aluminium alloy, or of the materials provided by the customer. Required properties of the tool material are achieved by application of relevant heat treatment when manufacturing.