Solutions of GRINS ENGINEERING are:

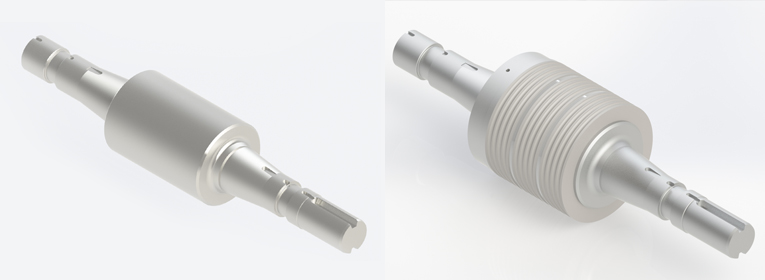

GRINS is a professional manufacturer of replacement equipment and spare parts for metallurgical plants; it offers cast iron and steel rollers for rolling mills. The company produces and supplies sheet and profile mill rollers with a nominal diameter of 280 to 680 mm.

GRINS provides a full cycle of design and production of rolls: from design of the process concept to production of equipment and serial production.

Due to precise design calculations, excellent mechanical properties and well-selected materials, GRINS ENGINEERING mill rollers are characterized by:

During the production of mill rollers for sheet mills, higher quality requirements are imposed on the following:

The form factors and diameter of the roller are calculated considering section thickness, maximum efforts, mechanical properties of the roll, operational conditions and process features.

GRINS ENGINEERING offers package solutions for design, development and reconstruction of mill rollers, and provides the following services:

Designing and modelling are performed with professional software.

Using its experience in rolling industry, GRINS ENGINEERING has developed a system of comprehensive quality control of production process and finished goods. The system includes control and sampling of material, models and prototypes, operational control of production process and testing of finished products. The developed technique includes control of finished rollers geometry by 105 calibration points.

High-tech equipment for controlling the quality of materials and finished products, as well as strict adherence to test modes at all stages of production, guarantees high quality of all supplied products.

Cast iron and steel rollers are manufactured using high-tech equipment by the world's leading manufacturers. Production lines and products are certified under the ISO9001 International Standard.